Updated December 2023

Energy companies use water throughout the life cycles of their projects and activities. It's our job to ensure that Alberta's energy industry uses water resources responsibly and identify where there is room for improvement.

Our Alberta Water Use Performance Report shows how water is allocated and used to recover oil, gas, and oil sands resources. This annual report is part of our larger industry performance program, which measures, evaluates, and reports on the energy development activities that we regulate.

Our report provides information about water allocation and use for four oil and gas extraction technologies:

- oil sands mining

- in situ operations

- enhanced oil recovery

- hydraulic fracturing

Because the volume of water used for conventional oil and gas drilling and operations is typically quite small, it is not discussed in the report. Water used for refining and processing activities is also not included in the report.

Report Highlights

- Only 13% of nonsaline water allocated to all industries in the province was allocated for oil and gas extraction.

- The Alberta energy industry uses much less nonsaline water than its allocation; the industry used only 21% of their allocation.

- Every technology used to recover Alberta's energy resources requires a combination of nonsaline and alternative water.

- In 2022, 17% of the water used by the oil and gas industry was nonsaline, 1% was alternative make-up water, and 82% was recycled water.

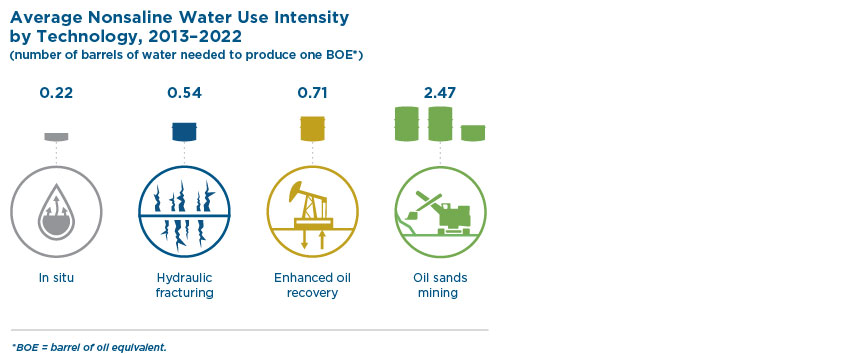

- Nonsaline water use intensity across the energy industry has decreased by 21.6% since 2013. The oil sand mining sector drives water use intensity and accounts for 81% of the nonsaline water used in 2022 by the energy industry.

- In 2022, oil sands mining used 17% more nonsaline water while producing 66% more hydrocarbons than in 2013. Consequently, from 2013 to 2022, nonsaline water use intensity decreased by 30% in the oil sands mining sector.

- The ten-year average (2013 to 2022) for nonsaline water use intensity in the oil sands mining sector was 2.47 barrels of nonsaline water per barrel of oil equivalent (BOE). In 2022, 80% of the total water used for oil sands mining was recycled water, and 43% of the make-up water came from surface runoff and groundwater from within the mining footprint. Recycling water and using surface runoff and groundwater reduces the volume of water withdrawn from the Athabasca River.

- The ten-year average for nonsaline water use intensity for hydraulic fracturing was 0.54 barrels of nonsaline water per BOE. Since 2013, the nonsaline water use intensity increased by 260%. Hydraulically fractured wells use water for the initial fracturing, but usually none after the well starts producing hydrocarbons. Consequently, water intensity for hydraulic fracturing wells is high during the first 12 months of production, falling to 0.12 bbl/BOE after five years of production for the average hydraulically fractured well.

- The ten-year average for nonsaline water use intensity for enhanced oil recovery was 0.71 barrels of nonsaline water per BOE. Over the past ten years, enhanced oil recovery producers have shown a 46% decrease in the technology's nonsaline water use intensity.

- The ten-year average for nonsaline water use intensity for in situ operations was 0.22 barrels of nonsaline water per BOE, a 48% decrease from 2013. This reduction is due to high rates of water recycling and the use of other alternatives to nonsaline water.

The figure below shows the ten-year average for nonsaline water use intensity for the extraction technologies discussed.