Updated June 2025

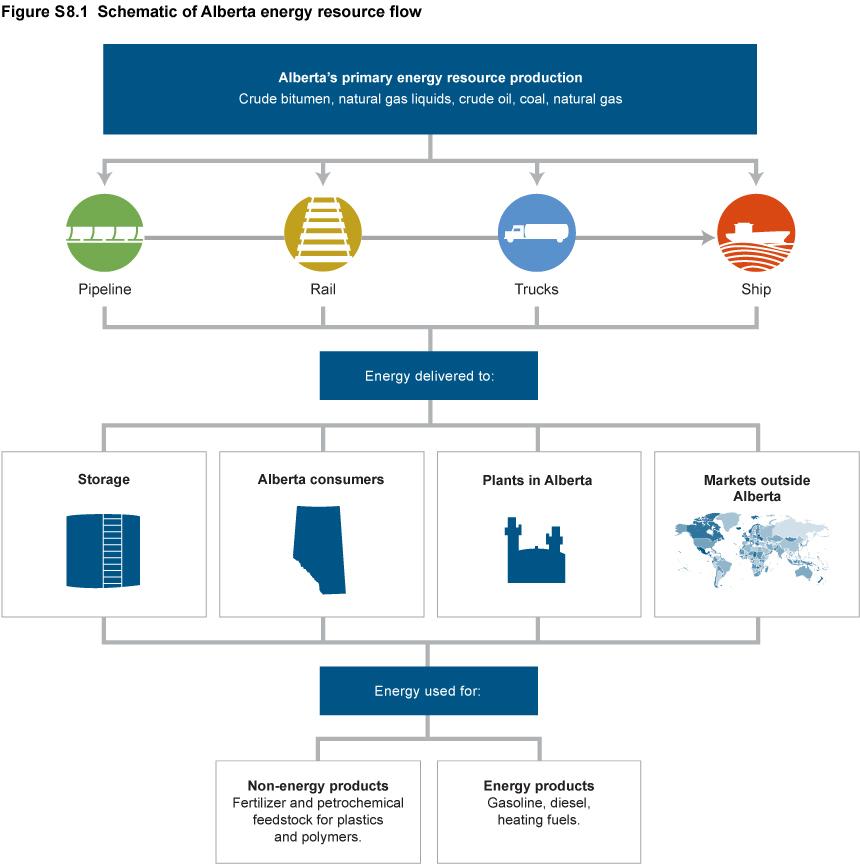

Oil and gas pipelines and railroads are among the transportation infrastructure needed to support the development of Alberta’s vast energy resources. Refineries, plants, and facilities turn these energy resources into marketable products (see Figure S8.1).

Pipelines

Thousands of kilometres of transportation infrastructure are needed to connect Alberta’s energy commodities to markets inside and outside Alberta. A network of pipelines has been built solely to transport energy resources. Other infrastructure, such as railroads and electrical transmission lines, is shared with other industries and Albertans.

The AER regulates over 449 000 kilometres (km) of pipeline in Alberta. This includes 12 000 km of natural gas utility pipelines for which the AER conducts surveillance and inspections, incident response, and investigations (as per a memorandum of understanding with the Alberta Utilities Commission). The Canada Energy Regulator regulates oil and gas pipelines that cross provincial or federal borders.

Alberta’s intraprovincial pipeline system is highly integrated and includes gathering, transmission, and distribution lines that transport hydrocarbons from producing areas to major distribution and processing centres within the province.

Pipeline gathering systems lower transportation costs versus rail and trucking; they reduce truck traffic and generate fewer safety and environmental concerns over product handling. Removal pipelines carry hydrocarbons to markets outside Alberta and are typically high-capacity pipelines traversing longer distances.

Oil Pipelines

In Alberta, most oil pipeline systems deliver oil to two central locations: Edmonton and Hardisty.

At Edmonton, pipelines transport crude oil to refineries in Alberta. Crude oil is also delivered to locations outside the province through Enbridge Inc.’s Mainline system and Trans Mountain Corporation’s Trans Mountain pipeline.

At Hardisty, crude oil can enter the Alberta Clipper pipeline, part of Enbridge’s Mainline system, for delivery to eastern destinations in Canada; TC Energy’s Keystone pipeline for delivery to Illinois and Texas; or Enbridge’s Express pipeline for delivery to the U.S. Rocky Mountains.

Transporting Heavier Crude Oil

Heavier crude oil, such as raw bitumen, will not naturally flow through a pipeline because of its high viscosity. It is typically mixed with a diluent to help it flow. Condensate and upgraded bitumen are the two main types of diluent used to lower the viscosity of raw bitumen for transport in pipelines. Naphtha, light crude oil, and butanes can also be used to get the bitumen to meet pipeline specifications. In some cases, heated pipelines are used to transport heavy bitumen.

The volume of diluent used depends on the viscosity of the crude oil and the type of diluent. Condensate is lighter than upgraded bitumen, meaning less condensate is needed to move bitumen through a pipeline. On average, heavy crude diluted with condensate will contain about 30% condensate, whereas heavy crude diluted with upgraded bitumen will contain up to 50% upgraded bitumen.

Typically, in Alberta, a small pipeline will transport condensate into the field, and a larger pipeline will transport the mix of heavy crude and condensate to a refinery where the condensate is usually recycled. When the condensate and bitumen mix is transported to markets outside Alberta, the condensate may be used as refinery feedstock or recycled and sent back to Alberta.

Natural Gas Pipelines

Raw natural gas, which includes other hydrocarbons and impurities, is transported from the wellhead by a gathering system to field processing plants. Field plants are usually located near the gas source where contaminants, such as water and hydrogen sulphide, are removed. Natural gas liquids (NGLs) may also be removed. Companies may extract more NGLs than is needed to meet pipeline specifications to get full value for the NGL components.

Once the natural gas meets pipeline specifications, it is compressed for shipment via a large transmission pipeline. Natural gas flows under compression through the transmission system from areas of high pressure to low pressure. Once the gas reaches its end market, distribution companies reduce the pressure for delivery through local distribution networks.

Railroads

North America’s railroad network is extensive, linking almost all major cities and ports across the continent. This network allows the movement of products across borders and markets. Within Alberta, the railroad system crosses the province’s major energy-producing regions. While pipelines allow shippers to access only certain markets, rail allows producers to place their product on railcars and ship it anywhere on the continent serviced by rail.

Trains are loaded at transloading facilities, which include pipeline-connected storage hubs and rail terminals. The oil industry typically uses a unit train, which carries only one type of commodity bound for one destination and generally has about 100 railcars. Demand for unit trains has grown rapidly in recent years because they can make a single nonstop run (they do not need to stop at different locations to offload different commodities).

Plants and Facilities

Upgraders

Upgraders are oil sands processing plants that upgrade bitumen into lighter hydrocarbon products. They chemically alter the bitumen either by adding hydrogen or by removing carbon. Sometimes, facilities do both. Upgrading improves the quality of the crude bitumen, producing a lighter, sweeter blend that can fetch a premium price.

In upgrading, most of the sulphur and other impurities contained in the bitumen are removed. The sulphur is either stockpiled or shipped to facilities that convert it to sulphuric acid, mainly used to manufacture fertilizers.

Upgrading also produces an off-gas that is high in NGLs and olefins. Companies have primarily used this off-gas as fuel in oil sands operations. They are now processing increasing volumes of off-gas to remove the NGLs and olefins, which are used as feedstock in the petrochemical industry.

Oil Refineries

Oil refineries use crude oil, upgraded and nonupgraded bitumen, and pentanes plus to produce a wide variety of refined petroleum products, such as gasoline and diesel.

Natural Gas and Natural Gas Liquids Processing Plants

Ethane and other NGLs are recovered mainly from natural gas processing. Gas reprocessing plants, often referred to as straddle plants, recover NGL components or NGL mix from marketable gas. They are usually situated on main gas transmission pipelines at border delivery points. Straddle plants remove most of the propane plus (C3+) and ethane. The degree of recovery is determined by the plant’s extraction capability, contractual arrangements, and product demand.

Field plants may send recovered NGL mix to centralized, large-scale fractionation plants where the mix is separated into its different components, such as propane, butane, and pentanes plus. A de-ethanizer tower with a turboexpander chills the natural gas to isolate ethane from other NGLs.

Ethane recovered at field processing plants, NGL fractionators, and straddle plants is shipped on the Alberta Ethane Gathering System to the Alberta ethane market.

Alberta’s petrochemical industry is a major consumer of ethane, which it uses to produce ethylene and polyethylene. Ethylene is one of the building blocks in producing packaging material, ethylene glycol, and styrene. The petrochemical industry also produces many other products, such as fertilizer.